What Is ACP Sheet Full Form?

The ACP Sheet full form can be describe as Aluminum Composite Panel, which comprises three layers. The first one is the Aluminum Surface, The next is the polyethylene Care, also known as the Mineral Fire Rated Core, and the third layer is The Aluminum Surface itself. Both are the same thing that you have a thin sheet at your lower end and a large sheet in the middle.

The material used is made up of two types. First, there is the plastic Polyethylene Core material and another fire Resistances material, and they are two different materials with distinct specialties.

The aluminum composite sheet is also abbreviated ACP. It’s also known as an Aluminium Composite Panel. It is an industrial material with a thermoplastic polythene base and a fire-resistant base layer sandwiched between two composed of aluminium sheets. Polythene isn’t an ignitable material, and it ignites and spreads.

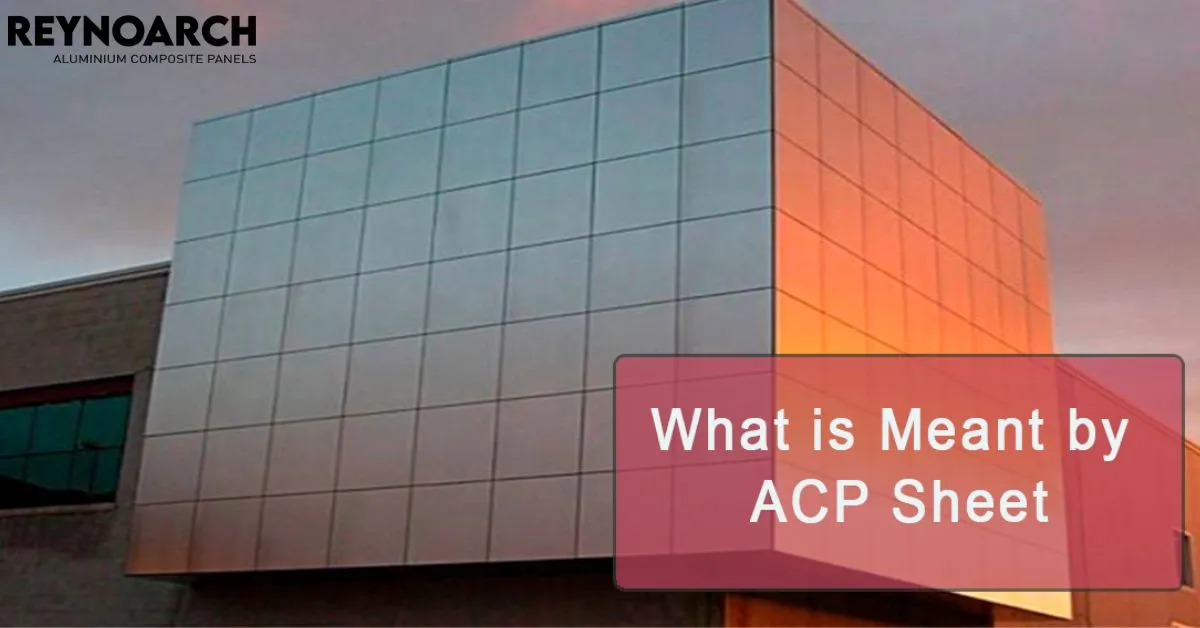

Exterior events typically involve the construction, partitioning, and building of exterior walls, in addition to being use for panels for curtain walls and when renovating older buildings.

Types of ACP Sheets

These are some of the most well-known types of ACP Sheets,

Fire Rated A2 Grade Sheet

ACP that is fire-rated can be employe to stop the fire. ACP that is fire-rated is made up of a specially-formulate mineral core of 70 percent minerals trihydride of aluminium, magnesium D-hydroxide, and 30% polymer sandwiched between two aluminium sheets. It’s use to lower the chance of fire from flames and smoke. Ulster India has considered one of the authentic sources of ACP fire-rated.

Generally speaking, aluminium composite panels with core materials fill with a fire-resistant mineral can be use. Any aluminium composite panel must be fireproof; however, it must comply with Fire Code.

The melting point of aluminium of 660 degrees C. Temperature at the burning process will range from 800-900 degrees Celsius, destroying skin and burning the heart.

Aluminium sheets are paint with polyvinylidene-fluoride, also known as PVDF or fluoropolymer, an epoxy or a coating. The most common thicknesses for aluminium composite panels are 3 millimeters, 4 millimeters, and 6 millimeters.

Because these aluminium composite panels offer many benefits, they’re often employe in various locations like exteriors and interiors. Outdoor activities usually comprise cladding, partitioning, and constructing partitions for exterior use and curtain wall panels. They also are utilize in the renovation of old houses. Indoor activities could include sealing lights, dust protection cleaning, display signs, to mention several.

Application of Aluminium Composite Panel

- ACP cladding that is use in signage for publicity and wall the cladding. Signboards made from ACP last for a longer time. ACP interiors are also use to embellish the interior, like curtain covers and for covering columns.

- A few years ago, the usage of ACP was restrict to outdoor uses, like the exterior cladding of buildings. ACP is now widely employe for both interiors as well as external uses.

- It’s use as an ornamental material for interiors, wall paneling for purposes, false ceilings, bathrooms, ducting doors, kitchens, homes, and hotel balconies.

Why Choose Us ACP Sheet?

Here are a few reasons why we pick ACP Sheets;

1. Fire Resistance

Many ACP sheets come with an FR grade designation, which means they are resistant to fire because the inorganic core of FR ACP is place within two aluminum layers. If the aluminium is already FR-proof, it cannot catch fire for up to 600 degrees C. The fire-resistant feature of ACP sheets ensures that they are safely use in anything from buildings to homes.

2. Environment Friendly

Aluminium composite can be describe as the most robust, eco-friendly material. It’s also is among the best-recycle substances in the world, which can be reuse without affecting the quality or value of aluminium that has been taken out of the sandwich panels. ACPs play an active role in energy-saving and solar heating systems, and they are energy-efficient, environmentally sustainable, and sustainable.

There’s a good chance that the panels you’re making use of for construction purposes could be made with recycled materials, or at the very least, a portion of them are made using recycle aluminium. A lot of panels might contain recycle materials. However, leftover pieces or complete panels being replace can be reuse, whatever it may be.

3. Lightweight Material

Any construction material will raise the costs of the general operation of the construction. The reason may be that a specific piece of equipment or vehicle is require to transport this massive material to the construction site. It will need more workers and a longer time to transport and place every piece when it finally arrives.

A few alternatives to ACP for signage and turnout, i.e., wood vinyl, wood, or fiber cement. However, these are heavy materials, and ACP panel panels offer lighter alternatives to the materials.

4. Strong Physical Properties

Aluminum Composite Panels or ACP sheets are characterize by their solid physical properties, making them the perfect material for cladding for building facades or outside. They are resistant to changing the weather because of their corrosion resistance.

ACPs can also handle temperatures ranging between -50deg and +80deg Celsius. Additionally, ACP is also known to possess excellent sound and heat insulation properties, which keep buildings cool. ACP sheets are UV-resistant and provide longevity for a long time.

5. Available in a variety of Colors

Composite panels can be cut in a variety of colors and styles. Therefore, you can select from a range of zinc, copper, and brush colors that correspond to your company’s particular design and color. The zinc colors also include quartz anthrax, pigment blue, red, orange, and pigment grey.

6. Modern and Stylish

ACP, or Aluminium Composite Panels. The “beaming range of exterior facade materials” gives a contemporary and elegant look to buildings’ exteriors. It is possible to make a statement by choosing stylish materials for the facade, like Virgo’s. It is also possible to use several colors to create an individual look.

7. Customization

ACP sheets let architects demonstrate their ideas more clearly. This is made possible by the simple routing and optimization capabilities present in ACP sheets. Due to their better routing characteristics, they can be shape to any shape like a concave, convex diamond, dome, and so on. Additionally, ACP sheets are dyeable in many shades to replicate natural inspirations, such as natural stone or wood bark.

8. Modern and Classy:

There are a few popular contemporary choices available in ACP sheets. You can update with just one change to give your building a fresher style. You will be different from others when you select something unique and adaptable. These qualities make your exterior classy. From the elite to the classy, all are making the most effective use of ACP in the present.

Uses of ACP Sheet

Here are a few ACP sheets use.

- ACP cladding that is use in signage as well as wall-cladding.

- Signboards constructed of ACP last for a longer time.

- ACP design False ceilings and dividers are quite common in the construction industry.

- Interior ACP can also be use to embellish the home’s interior, like curtain covers and for covering columns.

Advantages of ACP Sheet

Advantages of ACP Sheets can be describe the following:

- ACP Sheet is a very solid and rigid material even though it is lightweight in weight.

The material is accessible in standard sizes, making it much easier to transport materials to the site.

It is impervious to breakage, resistant to stains, weatherproof, and unbreakable. - Aluminium composite panels are a great option to reproduce natural wood and stone texture and color.

- Composite aluminum panels tend to be much less expensive than other cladding materials, making them a popular option for cladding.

- Because it is light in weight, it can be easily put in place without any difficulty.

The resistance to earthquakes is its main advantage compare to other material covers.

The thermal insulation properties of this product aid in conserving energy by insulating the interior from the outside temperature. - Composite aluminum panels can be describe as termite resistant with various wood cladding.

When its lifespan is up, it is possible to recycle aluminum again, making it a strong and sustainable material.

Disadvantages of ACP Sheet

The following are the major disadvantages from ACP Sheet,

- A aluminum composite panel needs to be waterproof properly; otherwise, water could get into the panel during rains and ruin the color of the interior.

- They are prone to damage and deformations in hurricanes as well as hurricanes.

- They are less resistant to UV rays, and the color could fade after some time. Additionally, they could shed their initial shine.

Warranty of ACP Sheet

Warranty of 10 years for two coats or 20 years for three coats provided by the manufacturers.

The warranty covers manufacturing defects that cause delamination, non-uniform color changes, or gloss reduction. The coating on the stove will not cause blisters, peels, or cracks after exposure to the elements, except for small cracks or scratches. But at Renobond you get ACP sheets at pocket-friendly prices with inclusive of 15-20 years of warranty.